Tradition and modern times – digitalisation in the crafts sector

Companies in the crafts industry, just like in manufacturing, manufacture (intermediate) products, but are typically smaller, less automated and work with a lower degree of division of labour based on made-to-measure and made-to-order production. In contrast to the industrial sector, many businesses in the crafts industry are still in the early phase of integrating digital technologies into their work processes. The reasons for this are mainly a highly traditional mindset as well as the small scale of companies and a low degree of division of labour which often do not permit an employee to be assigned exclusively to digitalisation tasks. At the same time, digitalisation in other sectors, especially in industry, is forcing more and more companies in this sector to rethink their business models.

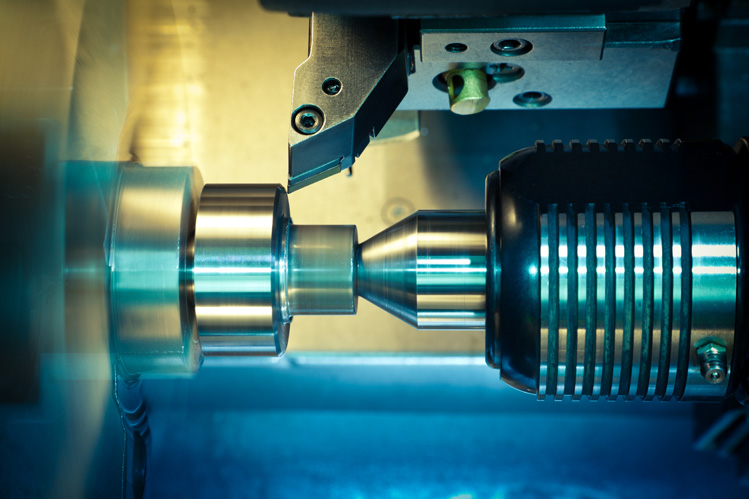

Just like in industry, computers and other forms of digital technology are becoming increasingly common in manufacturing operations of crafts businesses too. Carpenters, for instance, can design furniture models not only manually, but also using 3D computer programs. The complete data sets are then sent directly to machines or a 3D printer in the workshop. Smart machines are increasingly capable of performing especially strenuous activities. ‘Manual labour’ in the traditional sense could hence become less important in the crafts sector. Instead, the employees’ tasks will shift more and more towards customer support as well as production control.

Digitalisation has therefore enormous potential to offer for businesses in this sector when it comes to optimising manufacturing operations and can open up entirely new business models. Sales is another important aspect: Whilst historically the geographic reach of crafts businesses has been very limited, they can now address and serve a much larger number of customers through digital channels.